橡皮糖小医师

Dr. Gomitas

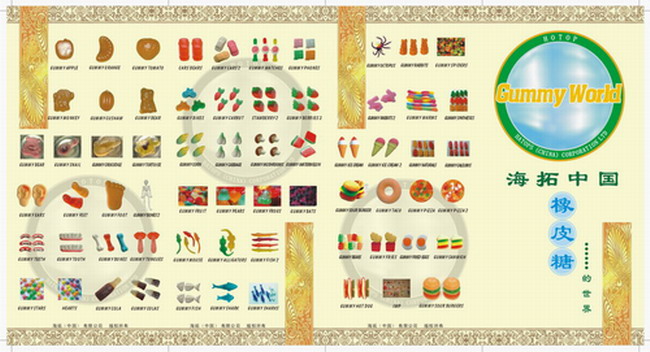

Hatops Food, Fun & Healthy, Confectionery & Candy and more

Custom-made Gummi Candy formulars (500 Kg) are welcomed... Export@HatopsFood.com

Hatops Food, Fun & Healthy, Confectionery & Candy and more

Gomi Process

Blending--Cooking--Mogul--Demolding--Sieving--Coating--Bag packing

Gummy candies start by blending corn starch, corn syrup, sugar, gelatin, color and flavor.

Cooking

These ingredients are weighed, mixed, and pumped into a candy cooker, a 128 foot long stainless steel coil.

Steam flows on the outside of the coil, cooking the candy inside.

The candy flows into a vacuum chamber to remove excess moisture.

Adding additive materials(color, flavor...)

Colors, flavors, acids, and fruit concentrates are added to the candy in a mix station.

Mogul

Next, the cooked candy flows to the starch moulding machine.

This machine, called a "mogul," moulds candy into distinct shapes.

The mogul uses a series of starch filled mould boards to make the candy shapes.

Demolding

The mould boards pass under a stamping machine that presses the shape of the candy into the starch.

Demolding

The mould board then travels under the hopper that is filled with the freshly cooked candy.

Here, the candy is pumped into the mould board, filling the shapes that will be the finished candy.

When full, the mould boards are stacked and allowed to dry.

Demolding

After 24 hours the mould boards are returned to the mogul.

The mogul empties the mould board by turning it over, allowing the candy and starch to fall into a rotating sieve.

Here, the candy is separated from the moulding starch.

Sieving

The candy moves onto a conveyor belt and is taken to a tumbler.

Coating

The candy is coated in the tumbler to keep it from sticking together.

Now the gummies are ready for packaging.

Bag packing

Form made candy, like Gummy products, are often packaged in a bagging machine.

This process uses a series of buckets which measure the amount of candy placed in each bag.

Bag packing

Once measured, the candy moves to the bagging machine which uses a flat sheet of plastic from a roll.

Bag packing

The sheet is folded in half and the seam is heat sealed forming a tube.

Bag packing

Heat sealing jaws close the bottom of the bag as they cut and seal the previous bag.

The new bag is filled with candy, and the jaws close the top of the bag.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.

Good Food, Good Life.